Project case

The completion and acceptance of the vacuum cleaning system project at Anhui Grain Reserve Depot indicates that the project has been successfully constructed and meets the expected design goals and usage requirements. This marks an important step for the grain depot in improving the working environment, ensuring the safety of stored grain, and enhancing work efficiency.

The following is some background information and significance regarding the acceptance of such projects:

The completion and acceptance of the vacuum cleaning system project at Anhui Grain Reserve Depot indicates that the project has been successfully constructed and meets the expected design goals and usage requirements. This marks an important step for the grain depot in improving the working environment, ensuring the safety of stored grain, and enhancing work efficiency.

The following is some background information and significance regarding the acceptance of such projects:

Core Functions of the Vacuum Cleaning System:

Efficient dust removal: It efficiently collects dust generated during grain depot operations (such as loading, unloading, conveying, and cleaning), significantly improving the working environment.

Safety prevention and control: It effectively reduces the risk of dust explosions, which is one of the most important safety goals in the grain storage industry. Vacuum cleaning is a key means to control dust concentration.

Protection of grain quality: Reducing dust accumulation helps maintain cleanliness in the warehouse and lowers the risks of pests and mildew.

Automation and environmental protection: It replaces traditional manual cleaning, being more efficient and thorough, reducing secondary dust emission, and being more environmentally friendly.

Compliance with regulations: It meets national regulations and standards for dust explosion prevention, occupational health, environmental protection, etc., in grain storage enterprises.

Significance of Project Acceptance:

Recognition of project quality: It indicates that the system design is reasonable, equipment installation is standardized, and construction quality meets the standards.

Confirmation of performance compliance: Tests (such as air volume, negative pressure, dust removal efficiency, noise, etc.) prove that the system's performance parameters meet the requirements of the contract and technical agreement, enabling it to effectively complete cleaning tasks.

Guarantee of safe operation: It ensures that the system itself complies with safety specifications (such as explosion-proof requirements, electrical safety, mechanical protection, etc.) and can be put into safe operation.

Project closure: It is an important milestone in the project construction process, marking the official transition of the project from the construction phase to the operation and maintenance phase.

Experience summary: It provides experience and reference for the promotion and use of similar systems in other grain depots.

Positive Impact on Anhui Grain Reserve Depot:

Improvement of safety management level: It greatly reduces the hidden danger of dust explosions and provides a safer working environment for employees.

Enhancement of warehouse appearance: It maintains cleanliness in the depot area and improves the corporate image.

Increase in work efficiency: Automated cleaning saves labor and shortens cleaning time.

Guarantee of stored grain safety: It creates a cleaner grain storage environment.

Demonstration effect: It sets an example for modernized and safe storage management in the grain industry within Anhui Province and even the whole country.

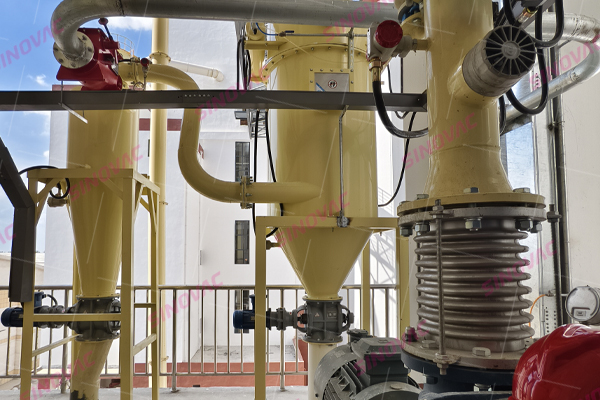

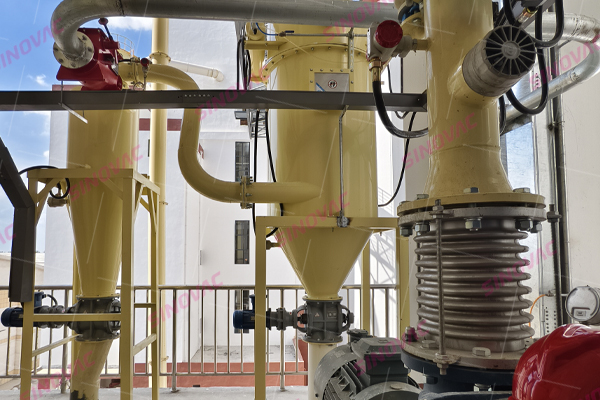

the vacuum cleaning system|Grain depot dust removal system

Contact Us

—

Address: 608, block a, National Convention and Exhibition Center, No. 1998, Zhuguang Road, Qingpu District, Shanghai

Tel: 15121023409 Manager Wang

We provide OEM production for more customers who really understand vacuum cleaning system.

© Shanghai Wellson Environmental Technology Co., Ltd.